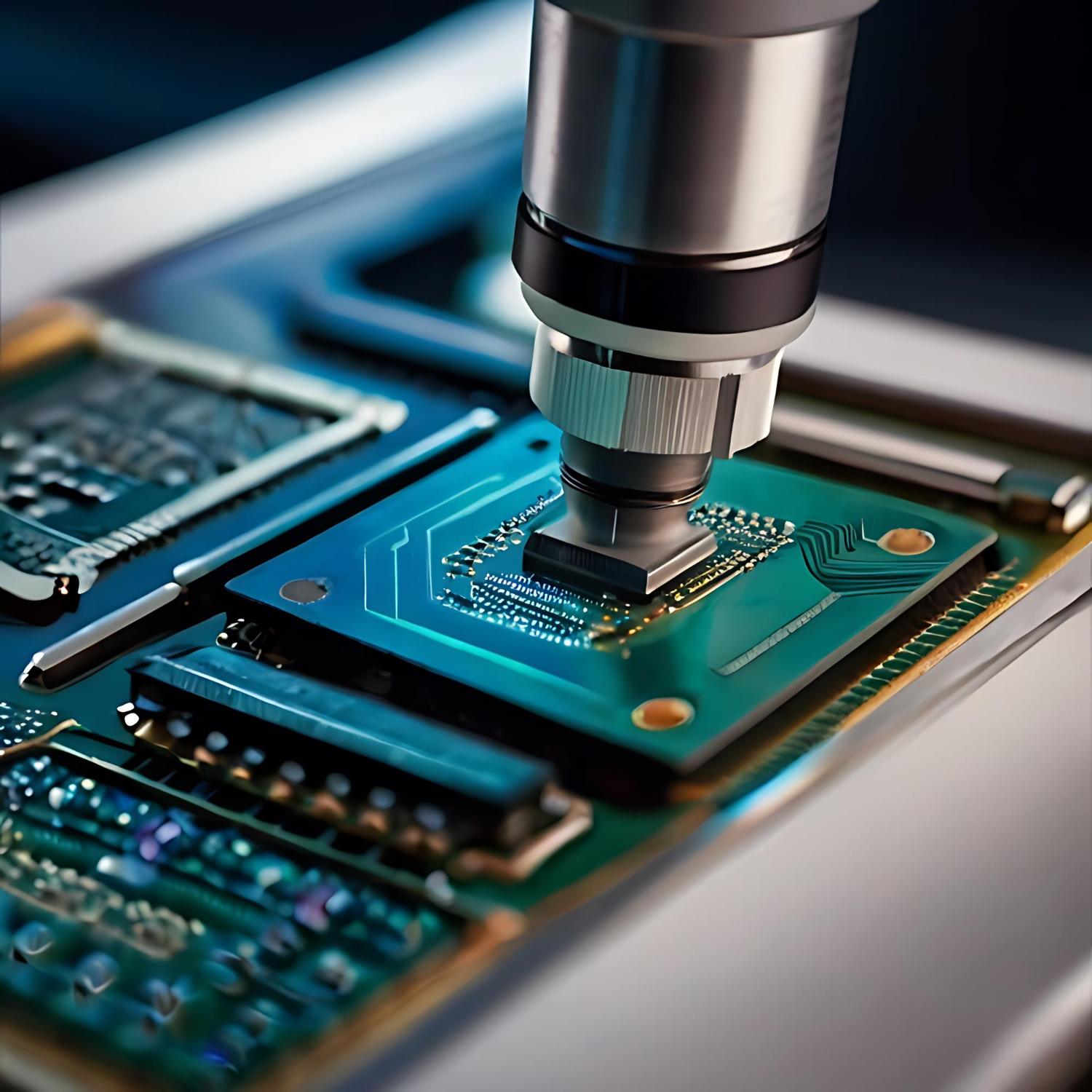

PCB Design for Efficient Manufacturing

Strategic Approach for Achieving Peak Performance With Cost-Efficient PCB DFM Solutions.

The process of PCB Design for Manufacturability (DFM) is a confirmation call for businesses to ensure their PCB designs are ready for effective large-scale production. Businesses can reduce possible manufacturing problems, accelerate production rates, and guarantee dependable PCB performance by simply implementing DFM ideation into practice. This approach is a foundational base for successful product launches and brings them into the market cost-effectively.

Effective Product Design Design for Manufacturing PCB with Elventive

Elventive PVT LTD has been providing product design for manufacture and assembly to various organisations since its establishment in 2021. Our network of experts uses advanced techniques grounded in engineering principles to produce PCBs that are both manufacturable and adhere to design specifications.

With our expertise in providing strategic design for manufacturing PCB, you can confidently handle electronic design issues. Elventive will ensure your final PCB product has a strong foundation to support your efforts for successful manufacturing and quality results.

Benefits of Relying On Our Services For PCB DFM

PCB Design for Manufacturability

Businesses are able to identify possible manufacturing issues right at the design stage. With PCB DFM services, they can evaluate the following factors:

- Layout Optimization: Examining the arrangement of components to minimise issues such as signal integrity problems and thermal management. Proper placement of components and traces to strengthen electrical performance throughout the concerned applications.

- Material Selection: Choose the right materials for the desired performance. Provided with suitable substrates and conductive materials, businesses can meet their product needs while considering the necessary element of manufacturability.

- Assembly Techniques: We evaluate different assembly methods, such as Surface Mount Technology (SMT) and Through-Hole Technology (THT), to ensure that the selected methods match your design expectations and promote efficient production.

Comprehensive Design Review

Including applications like DFAM design for additive manufacturing, our experts conduct a detailed review of the PCB layouts and provide necessary feedback based on their practical experience. The real value of this process stems out of:

- Electrical Design Automation (EDA): The use of EDA tools simulates circuit behaviour under various conditions and helps in identifying potential design flaws before production.

- Design Rule Checks (DRC): Rigorous checks to ensure compliance with industry standards and manufacturing capabilities, which helps businesses prevent issues related to trace widths, spacing, and pad sizes.

Prototyping Support

Elventive provides prototype PCB assembly to validate pre-production designs. In order to design a product, prototyping is a crucial step that allows you to::

- Test and Validate Designs: Create physical prototypes to test electrical and thermal performance. This process allows for adjustments based on actual data, ensuring that your PCB operates as intended.

Iterate Efficiently: Rapid prototyping enables quick modifications to the product design for manufacture and assembly and explores the scope for multiple iterations without the costs associated with full-scale manufacturing.

Cost Analysis and Optimization

In a competitive market, cost management is essential. Our DFM services include comprehensive cost analyses of your designs, focusing on:

- Life Cycle Cost Analysis (LCA): Assess the immediate production costs along with the long-term operational expenses associated with your PCB design. This wide view helps in ensuring that your design is manufacturable and economically lucrative.

- Value Engineering: Identify opportunities for design modifications that can lower costs without compromising quality. This may involve redesigning components for easier assembly or selecting alternative materials that meet performance standards at a lower price.

Process Overview

Elventive will make your PCB design into a manufacturable product with a systematic process, including:

1. Design Submission

Businesses must upload their PCB design for manufacturability files through our secure platform. This simple procedure guarantees an easy onboarding process for a more in-depth conversation.

2. DFM Assessment

Using advanced engineering tools to conduct a thorough analysis of the given PCB design allows for identifying issues that could affect manufacturability.

3. Feedback Loop

Collaborative feedback process that allows businesses to assimilate our findings and make necessary adjustments based on our judgement.

4. Prototyping:

Validate your design with rapid prototyping to enable quick iterations based on performance tests.

5. Finalization and Production

Approved designs transition into total production where every PCB unit meets the quality standards of the given industry Elventive is working for.

Technology and Equipment

Elventine uses the following modern assets to filter out the appropriate design for manufacturing PCB which will work well with the concerned machinery:

Enables accurate modelling of PCB layouts to visualize precise representations of the given PCB designs.

Simulation tools assess the design’s electrical performance, thermal characteristics, and mechanical integrity under various conditions.

Certified under ISO 9001:2015, Elventive conducts thorough checks of every PCB and identifies potential defects before production to maintain quality throughout its large-scale manufacturing process.

Your product needs to perform well in the market, and Elventive has the necessary resources to ensure your PCB designs are ready for successful manufacturing. Request a Free DFM Consultation to learn how we can improve your PCB manufacturing process and help bring your final product to market with no excessive costs incurred along the way.

FAQ

1. What is Design for Manufacturability (DFM)?

Design for Manufacturability (DFM) is the process of designing a product in a way that makes manufacturing easier, more cost-effective, and efficient. By considering manufacturing constraints early in the design phase, DFM helps reduce production issues, errors, and material waste. For PCB design for manufacturability, this includes selecting materials, minimizing complex layouts, and ensuring that the design can be produced within standard manufacturing capabilities, leading to smoother production processes.

2. Why is DFM important in PCB design?

PCB DFM is crucial because it helps avoid costly manufacturing errors and delays. A well-executed design for manufacturing PCB reduces issues like misalignments, poor solder joints, and component fit problems, ensuring the final product is reliable. By applying PCB design for manufacturability principles, designers can ensure their boards are easier and cheaper to produce while maintaining quality. This also shortens production time, minimizes rework, and improvises the product’s performance and associated reliability.

3. What are common challenges in DFM for PCBs?

Some common challenges in PCB DFM include ensuring proper component spacing, maintaining signal integrity, and minimizing thermal issues. Designers must also consider the limitations of design for manufacturing PCB processes like material selection, board size, and trace widths. Failure to address these can lead to manufacturing problems, such as soldering defects or mechanical stress. Complex designs or tight tolerances often require adjustments during production, increasing costs and time.

4. How can designers ensure their PCB designs are manufacturable?

To ensure a PCB design is manufacturable, designers should collaborate with manufacturers early in the process. Following PCB design for manufacturability guidelines, such as using standard materials, maintaining appropriate spacing, and considering manufacturing tolerances, can help. Running design checks for potential issues like signal integrity or heat dissipation, and using PCB DFM tools, also ensures the design aligns with production capabilities. This proactive approach helps avoid costly errors during fabrication.

5. How does Design for Manufacturability (DFM) differ from Design for Assembly (DFA)?

While product design for manufacture and assembly focuses on optimizing a product for ease of production, Design for Assembly (DFA) concentrates on simplifying the assembly process. In PCB design for manufacturability, DFM ensures the board is manufacturable with minimal errors, while DFA ensures the components are easy to assemble and integrate into the final product. DFA looks at minimizing the number of parts and streamlining assembly steps, while dfam design for additive manufacturing deals more with fabrication processes like drilling, etching, and soldering.