Precision Planning, Flawless Execution: The Elventive Mantra

Our holistic approach includes thorough analysis, detailed planning, and flawless execution to ensure your specific needs are met.

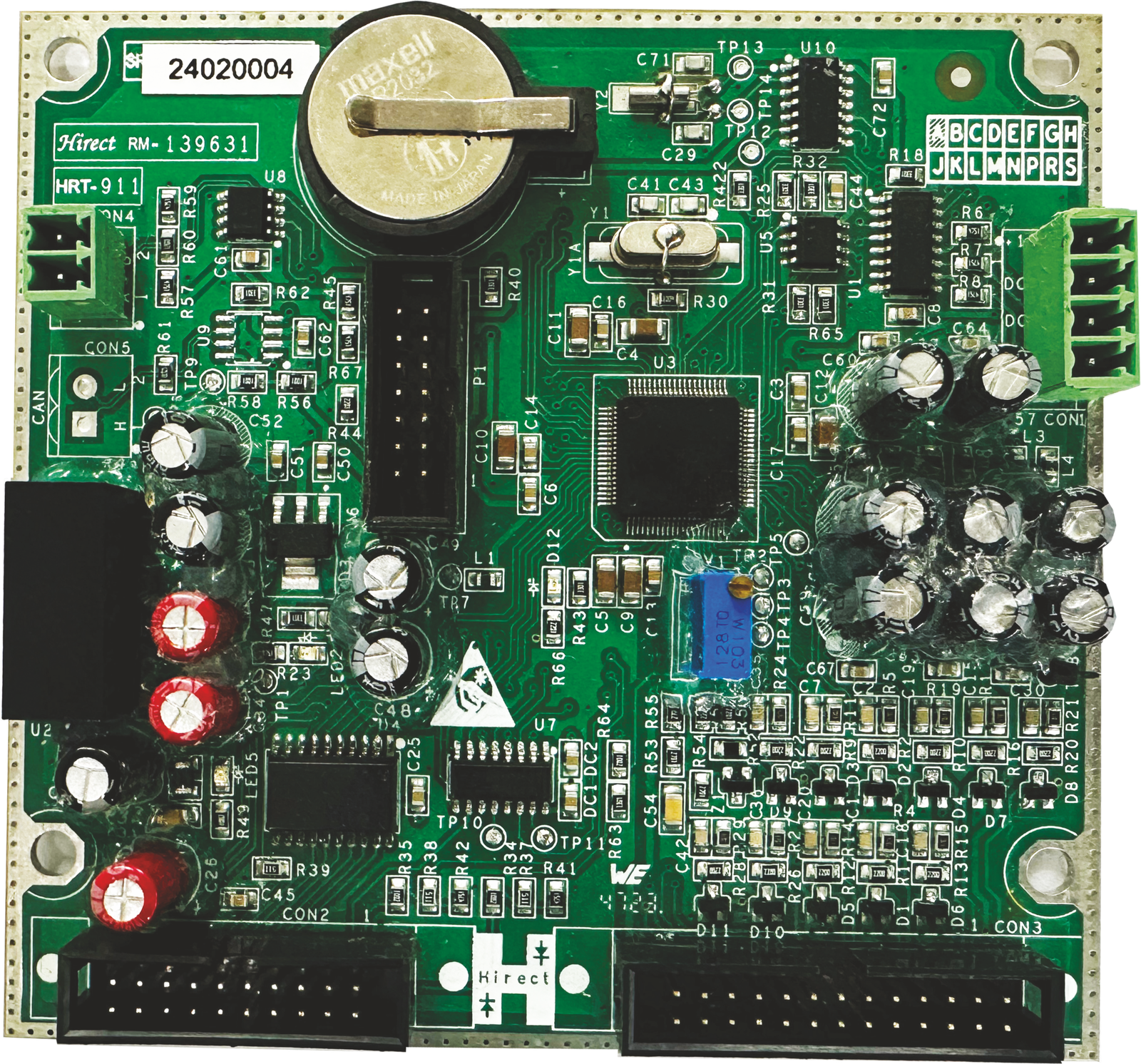

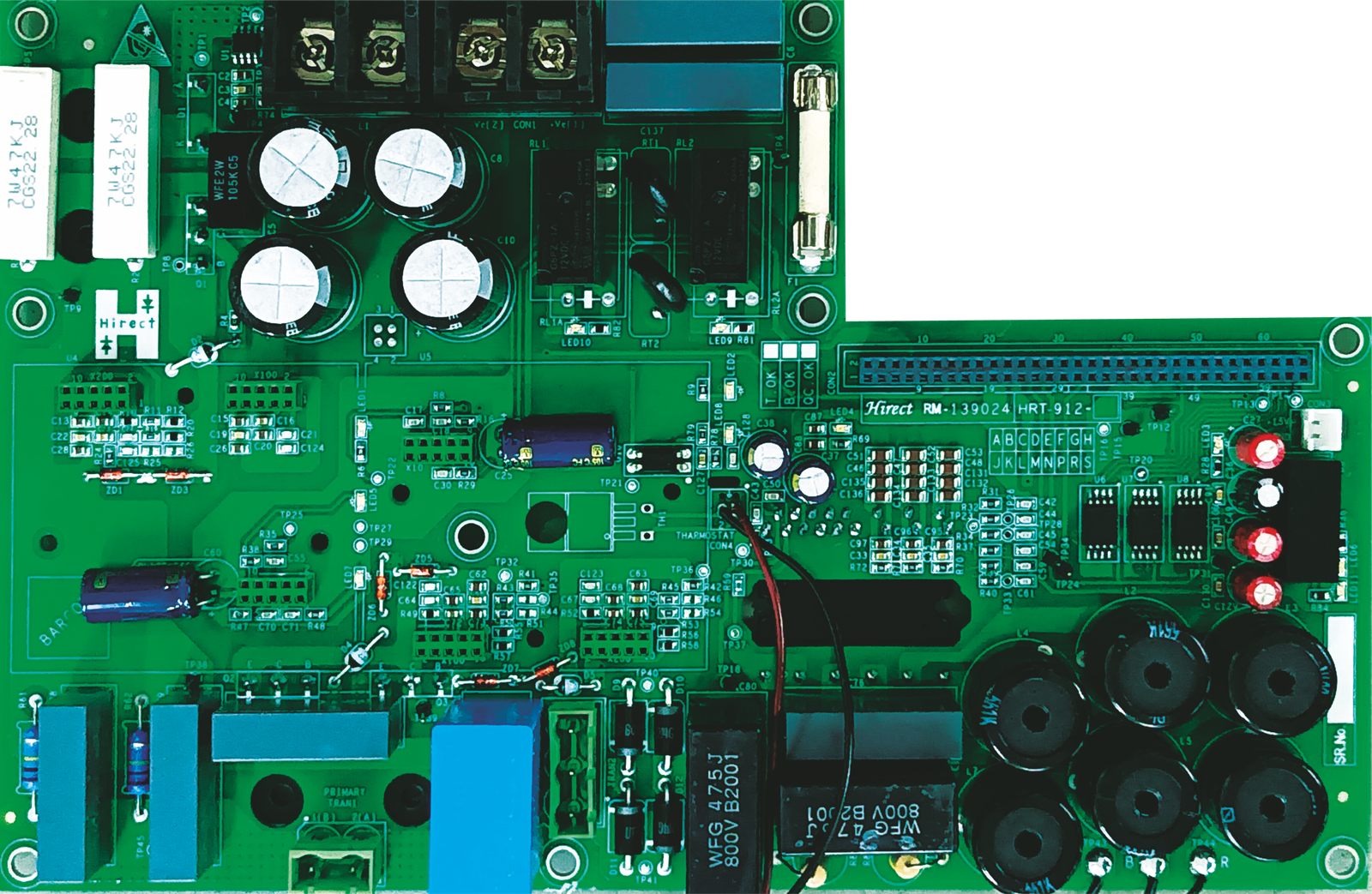

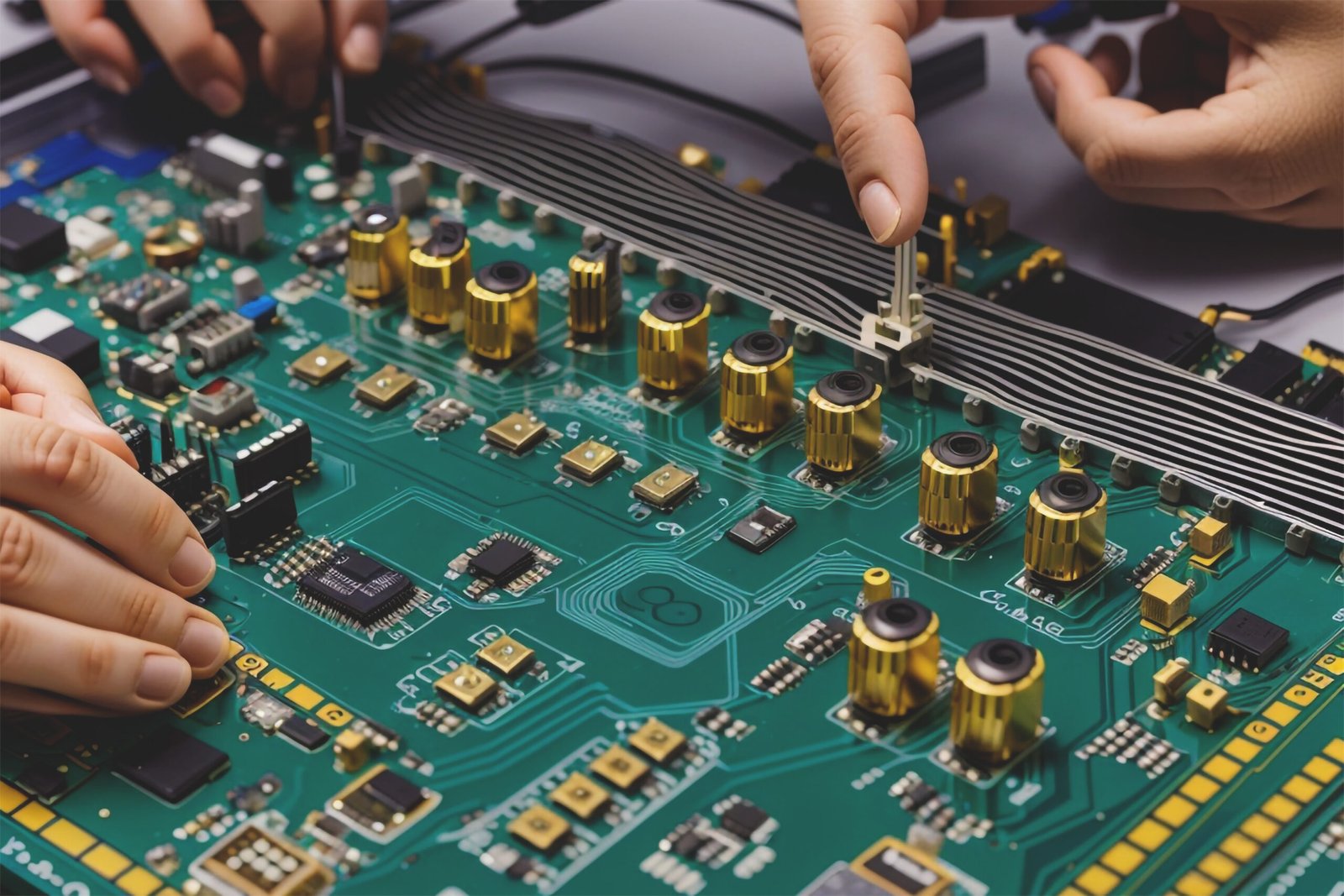

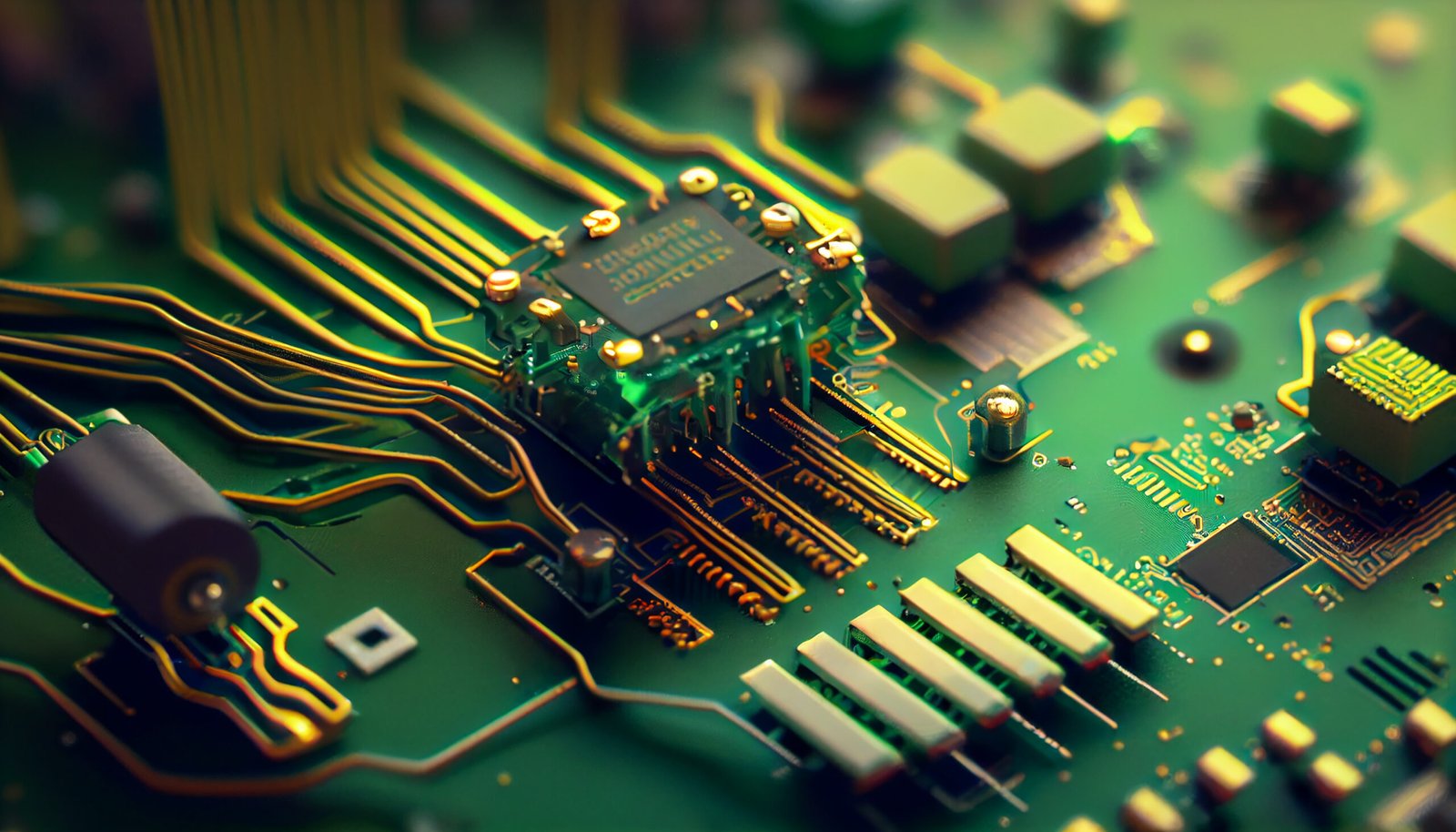

We offer expedited PCB fabrication services for standard FR-4 and high-end rigid, flex-rigid, and flex printed circuit boards. Our PCB assembly solutions accommodate prototypes and both small and large volume builds without mass production commitments. Our assembly facility features conventional through-hole and state-of-the-art surface mount technologies, including double-sided reflow, fine pitch, and BGA technologies with X-ray inspections.

The assembly facility has a Fully Automated SMT Line with an Automatic PCB Loader

Yamaha YCP10, Automatic Solder Paste Printer with 2D Post Print Inspection

Yamaha S20 fully Automatic SMT Pick and Place Machine with STD Hybrid Dispense SMD-CR-S14HAO

7-Zone Air Reflow Soldering Oven

Conveyorised system facilities insertion line for PTH components

Solbot S400 – Temperature controlled automatic wave soldering machine

OMRON S500 Automatic Optical Inspection (AOI) for high density ICs and High accuracy products

Strict process control with inspection in each stage and test equipments & test jigs to ensure quality

Fully ESD controlled manufacturing Environment with specialized ESD Storage Racks, Assembly Tables and Bins

Pallet facilities for quick and accuracy assembly

Ensuring Superior Quality in PCB Manufacturing

Explicit Quality Assurance Protocols for PCB Assemblies is crucial to ensure reliable and long lasting electronic products. At Elventive, we deliver assembled PCBs that exceed customer delight through rigorous quality control, advanced manufacturing techniques, and a culture of continuous improvement.

Our Quality Management System (QMS) oversees every production stage, from raw material inspection to final product testing, ensuring the highest quality PCBs.

This commitment to excellence both in terms of operations and quality is demonstrated by strictly adhering to the rules of Theory of Constraints.

Versatile PCB Products